Purpose of EFEM

- Improved Efficiency

- Reduces manual operations, enhancing throughput.

- Process Accuracy

- Ensures precise wafer positioning during transfer.

- Contamination Control

- Operates in clean environments, minimizing human-induced contamination.

Value of EFEM System Integration

- Market Leadership

- Pioneering smart-process-ready equipment.

- Automation & MES Integration

- Enables unmanned wafer handling and real-time data communication.

- Expanded Market Scope

- Transforms from auxiliary to smart production equipment.

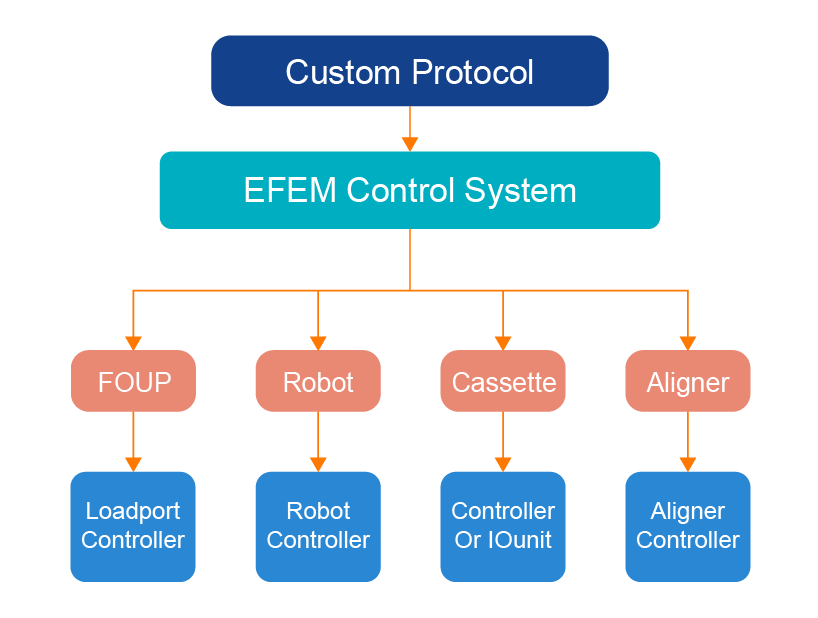

Control Architecture - EFEM

The Custom Protocol architecture is the fundamental control mode of ViewMove Technology’s EFEM system. This architecture enables ViewMove to directly interface with customers’ host systems through a simplified communication protocol, facilitating rapid deployment.

- The external communication protocol layer (Custom Protocol) supports flexible interfacing with external host systems, allowing customized communication protocols to be implemented based on project requirements.

- The EFEM control core layer (EFEM Control System) is responsible for module command control and resource scheduling.

- The simulation logic layer enables virtual-physical decoupling, allowing simulation testing and process verification in the absence of physical devices.

- The Smart Controller layer (Flexible Device) connects to third-party controllers through standardized communication protocols.

- RORZE (Robot), TDK (FOUP), etc.

- Beckhoff / Advantech (Remote I/O control).

- Architectural Features

Feature | Description |

Software-Hardware Separation | Control software and the hardware layer are fully decoupled through standard protocols such as Modbus, Socket, or RS232, facilitating simplified system upgrades and maintenance. |

Simulation-Real Integration Testing | With a built-in simulator capable of testing FOUP, Robot, Aligner, and other modules concurrently, system development and functional verification can be accelerated without relying on physical hardware. |

Scalable Modules | Built on a Flexible Device architecture, it enables seamless integration of customized functional modules and allows dynamic configuration tailored to the needs of semiconductor manufacturing processes. |

Vendor Neutrality | The Flexible Device architecture eliminates dependency on a single vendor’s controller, enabling customers to select the optimal combination of equipment according to their cost and performance needs. |

- Example

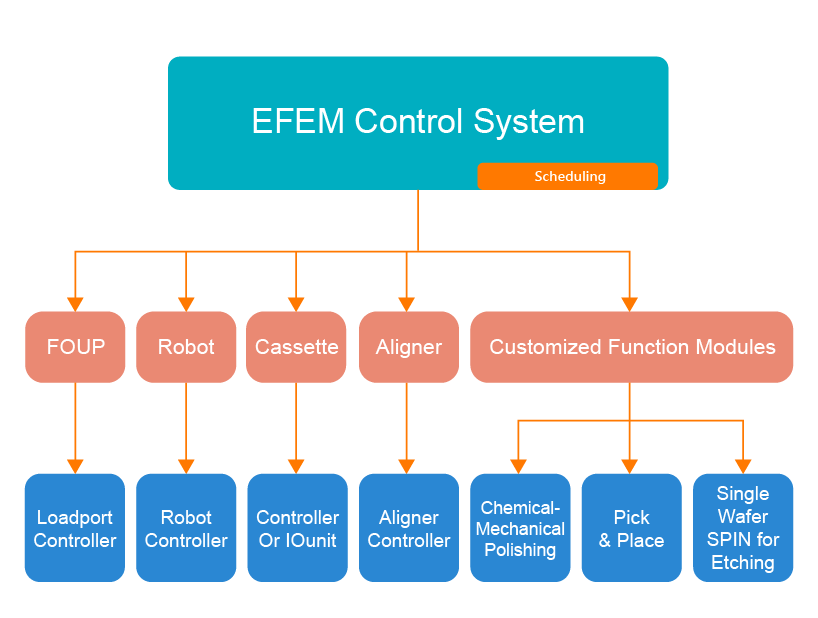

Control Architecture - EFEM + Scheduling

The control architecture offers high flexibility and compatibility, allowing it to adapt seamlessly to diverse customer equipment environments and requirements.

- Many automation machines commonly implement the entire process flow using a single large control program. The whole automation workflow is controlled by one program written with development tools, lacking modular layering and recipe abstraction.

Issue | Description |

High coding and debugging complexity | The process is tightly embedded in a monolithic codebase exceeding 10,000 lines. Development and compilation are time-consuming, and any single point of failure can disrupt the entire workflow. |

Poor scalability | Adding new controllers or modules (e.g., AOI, Plasma Cleaner) requires deep knowledge of the entire process flow and variable dependencies. The current architecture does not support localized changes, making integration highly difficult. |

Strong dependency on specific personnel | System maintenance relies heavily on the original developer. Complex process flow makes onboarding difficult, and the departure of key personnel poses a high risk of knowledge gap. |

Recipes and process flows are hardcoded | Due to the lack of recipe abstraction, process conditions and parameters must be modified through hardcoded logic. This leads to version fragmentation and makes testing and validation difficult. |

- Design Advantages of the ViewMove Scheduling Module.

Advantages of Modular Design | Improvements |

Each subsystem, including Robot and FOUP, possesses its own independent initialization routines and interfaces. | Modular architecture allows for isolated testing and debugging of individual components, ensuring that changes or issues in one module do not affect the overall system. |

Process flows are recipe-driven, enabling easy switching between configurations or multiple preset recipe groups by simply changing settings. | Support for new products or process flows can be achieved through configuration settings alone, eliminating the need to modify module source code. |

Scheduling management maintains a detailed task list for wafers, ensuring each wafer’s status is transparent and fully traceable throughout the process. | Eliminates dependence on developers’ tribal knowledge of the process logic. |

The system’s configurable design allows for quick and seamless integration of new modules. | Enables extensions without requiring full process refactoring, thereby lowering scalability and maintenance costs. |

The entire process flow can be defined and managed solely through configuration. | Enables customers to customize process flows independently, without requiring changes to the core Scheduling module. |

Although the initial development is more complex—requiring design of module interfaces, configuration of process flows, and error recovery procedures—once established, the system offers significantly greater flexibility, scalability, maintainability, and knowledge transfer capabilities compared to traditional development approaches.

- Example

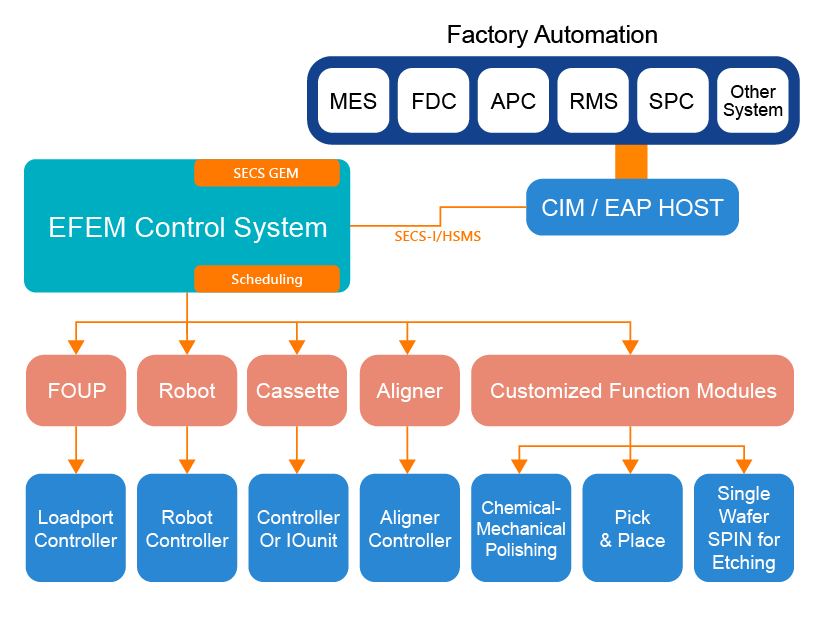

Control Architecture - EFEM + Scheduling + SECS

- The Necessity of Integrating the SECS/GEM Module.

Feature | Description |

Standardized Communication | SECS/GEM defines a standardized communication interface that enables seamless data exchange between process equipment and host systems such as MES or Factory Host. |

Enhanced Equipment Integration | The factory can rapidly deploy visual EFEM as a standard communication node. |

Support for Unmanned Production | Supports unmanned production by leveraging SEMI E84 standards to enable automated FOUP docking and transfer handshaking. |

Production Data Collection and Traceability | Supports production data collection and traceability by transmitting wafer processing status, exceptions, recipe details, alarms, and other key messages to the HOST. |

Support for Industry 4.0 | Supports Industry 4.0 by establishing a base framework that enables seamless adoption of advanced smart manufacturing solutions including AI, big data analytics, and cloud control systems. |

- Comparison: ViewMove vs. Market Drivers.

Feature | ViewMove | Commercial Drivers |

Integration | Native with HMI++, EFEM. | Needs external integration. |

Customization | UI-based VID/SVID/CEID. | Code-dependent. |

Industry Use | TSMC, UMC, ASE, Intel. | Varies. |

Support | Turnkey, on-site support. | Training only. |

- Example

Control Architecture – Comprehensive Comparison

- EFEM Control Architecture Comparison.

Layer | EFEM | +Scheduling | +Scheduling +SECS |

Comm | Slave Mode for Command Execution Interfaces supported include MODBUS, TCP, and RS232. | Scheduling Master Control Mode In addition to standard communication protocols, it also supports handshake control with equipment modules through PLC communication from multiple vendors, including Mitsubishi, Beckhoff, Omron, and Keyence. | Same |

Logic | Basic module control. | Recipe-based logic. | GEM/CIM compliant. |

Module Mgmt | Basic device control. | Resource scheduling. | External event handling. |

Monitoring | Alarm/History/Sim. | Same | Host reporting (SVID, ALARM) |

MES Host | No | No | SEMI SECS/GEM compliant. |

About us

- From simple to complex scenarios, the ViewMove architecture supports flexible modular expansion, allowing customers to rapidly validate during the development phase and seamlessly scale up to full factory production. You can focus on core equipment development, while the ViewMove team supports the integration of non-core components.

Feature | Strengths Description |

Industry Focus | Semiconductor & electronics automation. |

Tech Expertise | SECS/GEM, EFEM, PLC, CIM. |

Customization | Modular, protocol-agnostic systems. |

Partnerships | G2C+ Alliance, long-term customer projects. |

Global Deployments | Intel, WD, TSMC, and more. |